Last updated on July 24, 2021

Before any homes or businesses can be connected, six steps to be completed to “light up” each of the five fiber service areas (FSAs) in town. For each FSA, our distribution contractor, TriWire, attaches strand, hangs fiber, places MSTs, splices all of the fiber-optic cables together, tests each fiber, and validates the whole unit before it is ready for installations to begin.

FSA Distribution Network Construction

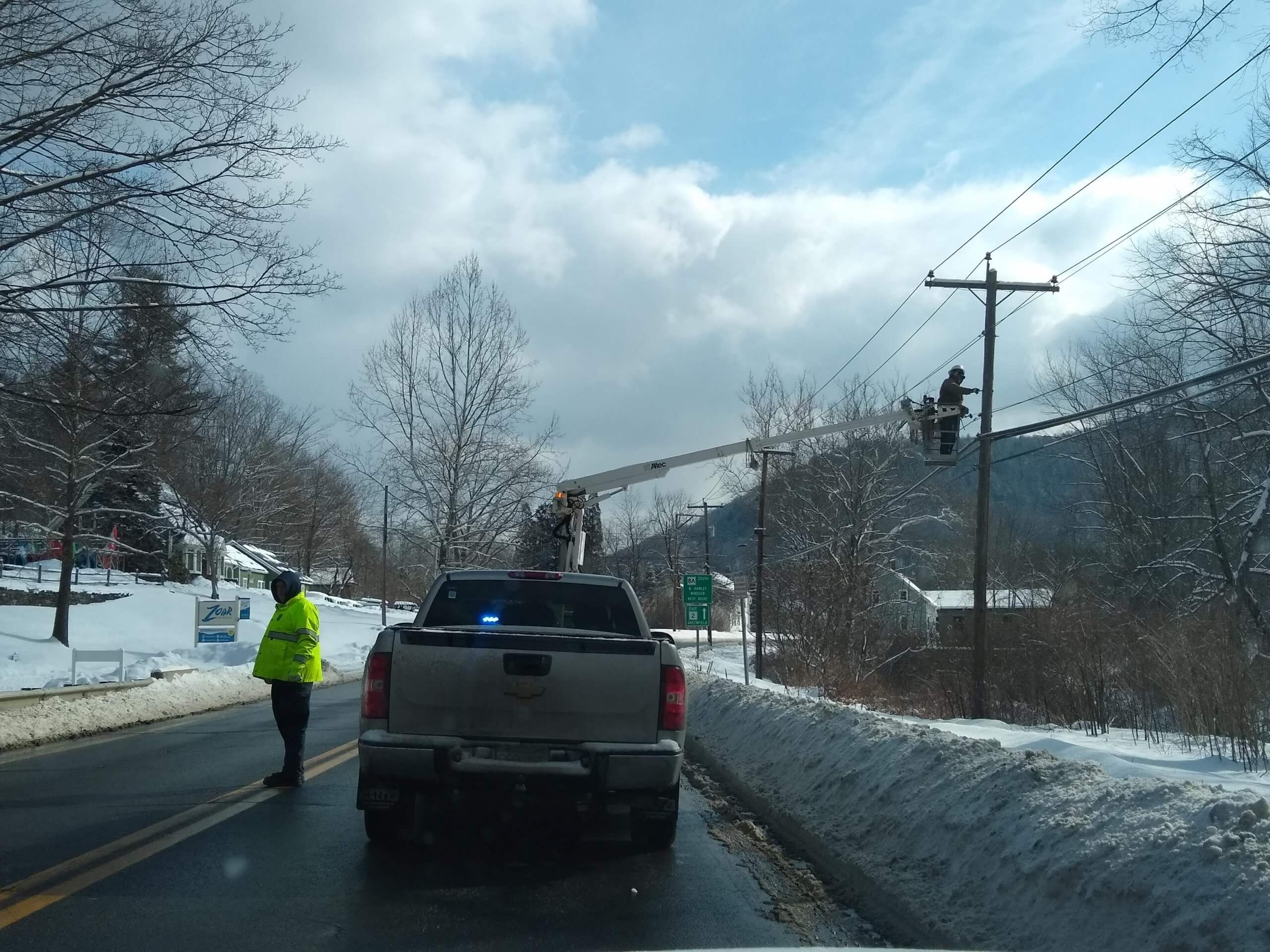

Sometimes called ‘fiber to the curb’, the distribution network construction will go through the same phases for each FSA to prepare the network for installations to homes and businesses in Charlemont. This work could not start until our ‘make-ready’ was complete – the work done by the utility companies to make space on each pole and make sure that it would be structurally sound to hold the new cables. This was completed and verified in January of this year.

Here is a breakdown of the six steps for each FSA:

Step 1, STRAND: TriWire crews attach brackets and steel strand cable to each utility pole that is a part of the FSA. If you follow the construction progress on the website, this step is listed as ‘Strand’.

Step 2, FIBER: TriWire crews lash the main fiber-optic cables to the steel strand. The distribution network terminates each fiber-optic cable in the network hub. This is listed as ‘Fiber’ when the construction stage is identified. Because our hub is in the center of the traffic calming area, all the fiber for each FSA needed to be hung in the traffic calming area to allow for a staged build-out of all FSAs when the DOT construction resumes.

Step 3, MST: TriWire crews hang a “tap” called an MST for each premises in Charlemont as of the time of our design completion in 2020. The construction updates will list this step as ‘MST Installation’.

Step 4, SPLICING: TriWire crews or a specialized sub-contractor splices each MST into the fiber-optic cable and the main distribution cables to each other, back to the hub. Because this step requires specialized skill and equipment, there has been a shortage of these folks across the northeast slowing construction in other hilltowns. Charlemont is working with our partners Westfield Gas and Electric (WG&E) and TriWire to accelerate this work as splicers are sourced.

Step 5, TESTING: TriWire crews or a specialized sub-contractor tests each fiber to make sure the splice is correctly done and there are no problems with the connection.

Step 6, VALIDATION: WG&E, Charlemont’s owner’s project manager, validates the work and then the town accepts the FSA as complete.

Once all six steps are complete for each FSA, installations can begin in that area of town.